Wet & Dry Process

VERTICAL WASHING MACHINE

These multifaceted machines are used in the processing of linen and garments with water as the medium of wash. Both the outer drum and the inner basket are made of tested stainless steel of AISI Grade 304. The perforations in the inner basket are precision punched and embossed in a CNC machine. The gap between the inner basket and outer drum is very low thereby reducing the amount of water consumed per kg of load (liquor ratio). This reduces the amount of chemicals and energy consumed. The inner basket consists of stainless steel beaters to provide a consistent lift to the garments.

SIDE LOADING WASHING MACHINE BELLY WASHER

Top loading, stainless steel 304 grade inner basket, and outer drum.

A safety main controller switch is provided—a safety door limit switch.

Calibrated water level indicator, large case iron drainage to ensure quick release of water. Available in both steam and electric heating options. stainless steel chemical dispenser.

TUMBLE DRIER

ECOTEX tumble driers come with an inner stainless steel basket. All our driers have a programmable controller capable of storing up to 5 programs. Features such as Auto reverse, Digital temperature indicator/controller, forward timer with pause timing and total time come standard with this controller.

All machines come with an Auto RH (residual humidity) meter thereby ensuring that maximum energy is saved (Optional).

The drive of the ECOTEX driers is via balanced closed grained cast ironed pulleys with matching V belts and pedigreed bearings. This enables the equipment to sustain radial and axial loads

The inner basket is double insulated with a high quality mineral wool held in place by fine aluminum sheet backing on loaded spring hooked ties. The Inner stainless steel basket is a fitted with CNC manufactured stainless steel paddles to ensure a smooth tumbling effect.

The high load capacity ratings, self cleaning lint screen and other designed features make this drier a space and energy saver and guarantees faster drying time.v As an option, dryers are also available in all stainless steel construction. Direct gas fired heating option is also available.

VERTOSTAR (Series 7.7D)

The Vertostar series 7.7 D (Garment Dyeing Machine) is a versatile machine with rugged design for many year of Trouble free service. The concept of washing garments with the aid of ozone (Tri Oxygen) dissolved in water is the innovative technology in washing capable of reducing chemical consumption and energy saving.

Salient Features:

Machine provides 1000 liters Dye bath exacuation tank to help increase effective loading.

High flow rate jets spray system to circulate the dye bath helps reduce entanglement.

Multi chemical / Dye tank color kitchen with stirrer can be provided (Optional)

Large sampling door for easy removeable of Garments during process.

Variable speed drive for selecting different RPM for slow / high spin dyeing.

Outer drum insulation for preventing heat loss of dye bath (Energy Saving)

Dual drain(Optional) can be provided for better management of effluent.

HYDRO EXTRACTOR

The inner basket and the outer drum are made of stainless steel and the inner basket is directly mounted on the drive motor.

The motor is suspended with a coaxial setup along with thermal and anti-humidity insulation. All the machines have the necessary door lock mechanism and continuous current braking system to ensure a simple and safe operation.

The design provides a quick, self-balancing noiseless, and vibration less performance.

DRY CLEANING MACHINE

Ramsons is proud to present its indigenously manufactures range of Dry Cleaning Equipment based on Italian technology. These machines will be for indigenous consumption and shall also be exported back to Italy. With all critical components such as the PLC , refrigeration, main door, motors, pneumatic valves etc. being imported from Italy and also because of the machines being manufactured by the highly qualified Ramsons production team, these machine are of the highest quality, but at an affordable price.

SPRINKLER (SPRINKLE WASH MACHINE)

Ramsons Auto Sprinkler Specially designed basket with heavy duty wedges for long life on denim pumice stone washing and external water barrier for automatic water sprinkling effect.

NEW GENERATION VERTOSTAR™ 7.7 SERIES

The Vertostar ™ Series has a versatile designs enabling it to generate all possible effects on the garment. The inner drum and beaters are specially designed for processes like Denim washing, stone washing and Dyeing unlike other European machines which are made for a specific application.

CAPACITY: 5 KG – 500 KG

BASKET VOLUME: 87 LTRS – 4905 LTRS

BASKET DIA: 280 MM – 1730 MM

BASKET DEPTH : 630 MM – 1900 MM

DOOR OPENING: 400 MM – 1050 MM

MOTOR: 0.5 HP – 30 HP

AIR PRESSURE: 6 TO 8 BARS

WEIGHT: 280 KGS – 7500 KGS

OPTIONAL FEATURES

De-Stoning Attachement

JET Spray Mechanism

Controlled Heating & Cooling (For Dyeing)

Color Kitchen

New Designed PLC

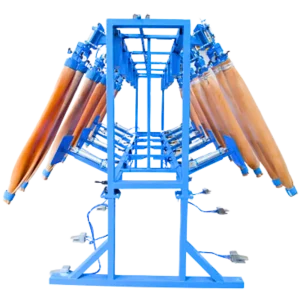

RAMAGIC

Ramagic is a compact sampling machine with multiple baskets rotating on a single axis. The entire machine is constructed using stainless steel. This is a must have for all apparel sample units.

DRY CLEANING MACHING

ECOTEX is proud to present its indigenously manufactures range of Dry Cleaning Equipment based on Italian technology. With all critical components such as the PLC , refrigeration, main door, motors, pneumatic valves etc. being imported from Italy and also because of the machines being manufactured by the highly qualified ECOTEX production team, these machine are of the highest quality, but at an affordable price.

Features:

Large still unit allows for faster distillation and recovery of solvent

99.8% of the solvent is recovered

Completely automated PLC Computer is easy to use and allows for additional programs to be stored

Multiple options such as dual heating, self cleaning button trap, additional water separator and sludge pumps are available on request

Largest sales and service network in the Indian subcontinent

A built in refrigeration unit and compressor come standard with these machines

ECO 6 is an economical model

WASHER EXTRACTOR

Features:

Fully Programmable PLC

24 Wash Programs can be stored

LCD Display showing complete messages (not just codes)

Ability to continue program from paused state (useful when there is a power loss)

Cycle time, wash temperature and water level are programmable

Standard 5 soap connection upgradeable to 12 soap connections

Provision to fit external, automatic soap dispenser

Auto chemical dosing via external dosing pumps is possible

Japanese Inverter Drive(standard on all machines)

Washing and Extraction RPM’s are programmable

Enables uniform acceleration of the motor. Prevents voltage fluctuation from affecting the motor.

LCD display showing current drawn, frequency, output voltage etc.

Heavy Duty Bearing Housing & Pulley

European (Swedish) manufactured Bearings designed to operate at 1000+ RPM (higher G Force)

High grade, close grain cast iron (GG25), balance and rugged bearing housing and pulley for longer life

Specially designed IMPORTED LIP seal which provides a longer life than conventional oil seals

Suspension

All Ramsons washer extractors are free standing machine enabling high extraction speed/G forces.

Dual suspension technology – Spring suspension on top & shock absorber/spring suspension on bottom

Springs manufactured out of high yield strength spring steel alloy preventing any deformation

Complete Chrome Piston Rod shock absorbers generate a longer life time

OZONE MACHINE

The concept of washing garments with the aid of ozone (Tri Oxygen) dissolved in water is the innovative technology in washing capable of reducing chemical consumption and energy saving.

Features:

Ozone Finishing does not need water and hence reduces water consumption drastically.

Back staining of the color on the Garment is totally eliminated resulting in a better end quality.

Better control on the shade matching & wash consistency is achieved as the ozone finishing is a Dry Process.

Higher Productivity is attained as ozone finishing is much faster than the conventional bleaching.

This is an Eco friendly process as the ozone gas is passed through a specially designed exhaust system which disintegrates the ozone into oxygen.

Reduced water consumption and conventional bleach is eliminated resulting in lower maintenance cost of the ETP.

CONVEYORISED SPRAY BOOTH

This is a complete PP spray booth with conveyorized mannequins and hot chamber for higher productivity and better quality. This system comes with a spray booth capable of holding 2-6 mannequins, while a conveyor with multiple hanging mannequins and a hot chamber comes standard. The hot chamber ensures faster drying of PP, thus reducing the waiting time. The hot chamber further prevents formation of PP spots on the garment.

DRY PROCESSING

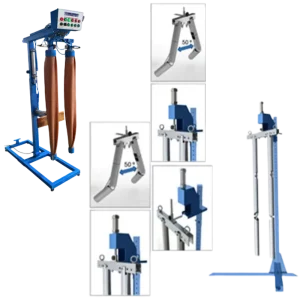

This flexible robo can be used for both horizontal and vertical brushing operations on denim trousers. This machine has a rigid base frame with a tubular support mounted on a hinge for easy change over from horizontal to vertical position and vice-versa.

This robo is fully automatic with features like pneumatically operated lifting, knee support, quick air release and automatic air filling controlled by german make pressure controllers.

BRUSHING MANNEQUIN

These mannequins are used for Brushing and Chemical spraying on denim garments.

A full pneumatic control for easy operation and maintenance comes standard.

A special butyl rubber balloon ensures an extra long life.

A quick exhaust valve enables faster releasing of air.

The air allowed into the right and left balloons can be different thereby allowing for more control.

The balloons are adjustable for different waist sizes.

The design is rigid while at the same time very easy to operate

PP SPRAY BOOTH

ECOTEX spray booth come standard with an exhaust and the recirculating water curtain ensures a clean atmosphere and working area.

ECOTEX spray booth are available in fully stainless steel construction of 304 and 316 grade which ensures a long and corrosion free life.

A new feature in our stainless steel spray booth is the floating tank which is used both for operator assistance and and also for the residual spray to go into the perforated tank for recycling.

The water curtain ensures that all the particles from the air are absorbed and mixed with the water which can be regularly discharged without any contamination; the exhaust will therefore be free from any spray particles.

The exhaust system can be placed on top or behind the spray booth. The high exhaust is essential for compliance as the fumes should not reach the operator.

We manufacture spray booths in different sizes to accommodate from 1 to 6 robos.

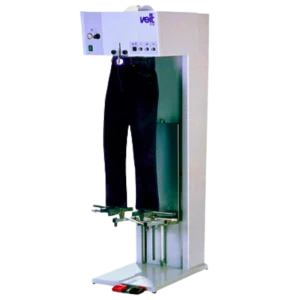

BODY PRESS

Brisay BRI 231E/101

Efficient and economic, the integrated steam drier and powerful hot-air blower give a good cost/ benefit result and a quick payback. Loading position has 4 different settings. Carriage of the hem tensioning device can be moved towards the operator, hence there will be no wrinkles behind the knees. Active and freely adjustable stretch-control is standard.

STEAM PRESS & ELECTIC / STEAM PRESS IRON

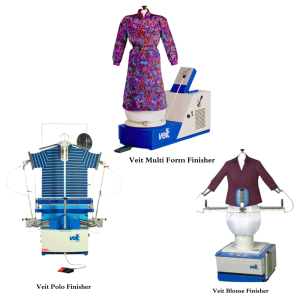

FORM FINISHERS

TROUSER TOPPER

Multi-purpose modular design offers every desired solution from the simple and cost

efficient to the high end solution

Patented electromotive carriage drive of the hem clamping device ensures problem free finishing of even sensitive stretch fabrics without any damage

Wearl ess waistband tensioning devices for a long life

Increased pressure and air volume flow due to optimized air systems forideal results

Modular system allows a combination of the base unit with waistband longitudinal or

lateral tensioning as well as many other options